Perlite Basics

and beyond

What is Perlite?

Perlite is a naturally occurring glassy volcanic rock. When heated at extreme temperatures, it pops like popcorn, expanding up to 20 times its size. The size and grade of expanded perlite determine its use.

Perlite’s versatility is due to its unique characteristics:

Lightweight

Fireproof

Insulating

Sterile

Pest-Proof

Decay-Proof

Perlite is everywhere

From a lightweight filler in cultured marble to a matting agent in cosmetics, perlite is used in multiple industries for varying applications.

Temperature Insulation

Temperature Insulation

Treatments

Construction

Insulation

Filtration

Filtration

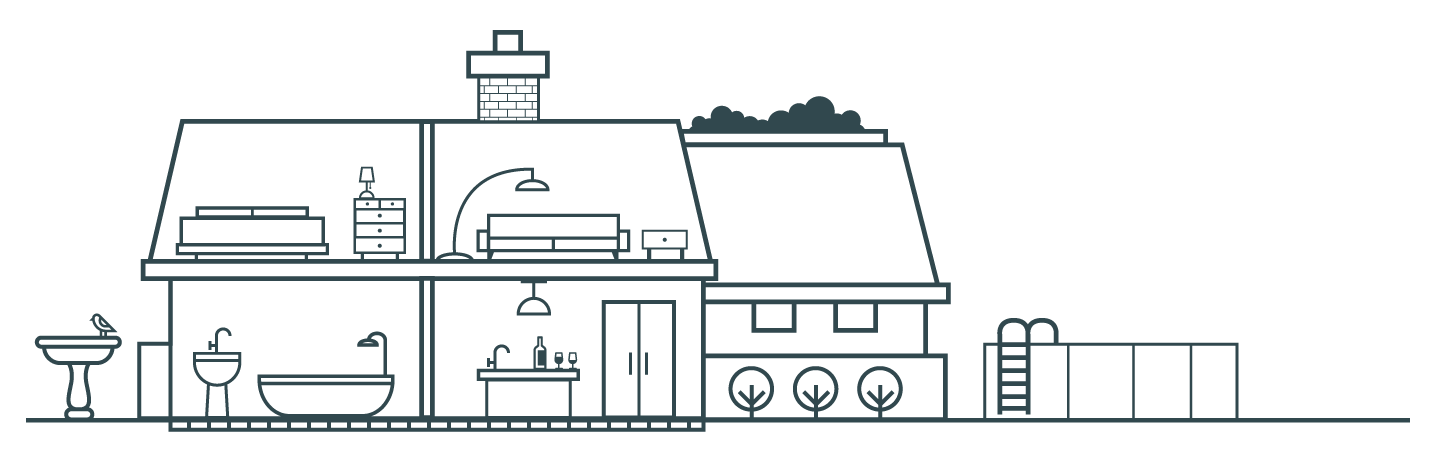

Perlite Lives Here

The applications for expanded perlite are all around you. Hover over and explore the many ways perlite was used in and out of this house.

Green Roof Soils

Perlite is great for green roof soils because it is lightweight, low maintenance, holds water and nutrients, and is cost-effective.

Chimney Liner

Due to its non-flammable nature, perlite is often used in fire retardant applications such as chimney liners.

Fireproof Insulating Door Cores

Perlite is the perfect filling material for door cores because it is naturally lightweight, inorganic, insulating, non-combustible and fireproof – giving it a high R-value.

Garden & Soil Amendment

Horticultural perlite provides superior drainage, retention of water and nutrients, weed control, strong capillary action and more.

Cast Stone, Brick & Statuary

As a lightweight filler, perlite provides outstanding strength, durability, and cost savings to many kinds of high-volume projects.

Cement Stucco

Perlite is used extensively as a lightweight aggregate material in concrete stucco as it offers thermal insulation, fire resistance and more.

Pool and Pond Water Filtration

Natural and non-hazardous, perlite quickly and efficiently filters even the murkiest of waters using about half of what it takes for diatomaceous earth.

Cultured Marble

Perlite is an excellent ingredient for cultured marble products like sinks and bathtubs because of its light weight and versatility as a filler.

Plaster Aggregate

Using lightweight perlite plaster saves on transportation, application and structural costs, and offers superior insulation against noise, fire and climate.

Textured Paint

Perlite is a cost-effective bulking agent for paint, providing texture and consistency – and its white color helps with the pigmentation process.

Joint Compound

Perlite’s natural bonding qualities make it a great additive for joint compounds. It also is easy to work with and provides greater uniformity.

Insulating Concrete

Perlite infused lightweight concrete provides better noise reduction and thermal insulating properties than conventional concrete and can be used in many applications.

Under-slab Insulation

Easily installed in bags below concrete floors, perlite is a natural, inorganic insulation product that does not rot, support combustion or provide a habitat for rodents.

Beverage Filtration

Perlite filter aids are sterile, inert, impart no taste or odor, and meet the Food Chemicals Codex standards for quality and purity in the beverage, food and pharmaceutical industries.

Ceiling Tile

Perlite is the perfect aggregate for ceiling tiles because it is light weight, insulating, crack resistant, vermin proof, fireproof, and sound insulating.

Masonry Loose Fill

Lightweight perlite pours easily to fill all cores in various masonry applications, providing excellent insulation and high resistance to fire, water, rot, vermin and termites.

Insulated Tile

Because it is lightweight, naturally insulating and resistant to water, rot and cracks, perlite is widely used to make insulated tiles.

The Path of Perlite

Volcano

Perlite forms when lava is submerged in water and cools so quickly the water is trapped in the glass. Raw ore is very dense, but softens at extreme temperatures.

Mining

This is not your typical mining process. It's all done above-ground using an open-pit method of ripping with a bulldozer and, when needed, blasting. It's safer, more environmentally friendly and sustainable, with less than 1% of perlite mined to date.

Transportation

Perlite is transported by train as dense ore to reduce costs and environmental impact. One train can transport as many as 300 trucks and produces 8 times less CO2 and 3 times less nitrogen emissions.

Processing

Raw perlite ore is crushed, dried, screened and then heated at temperatures ranging from 1600 to 1800 degrees F. When it pops like popcorn, it expands up to 20 times its original size. And since only the physical form is altered, there are no by-products.

Final Form

Once expanded, perlite turns from gray to white, is lightweight and has glass bubbles that can hold water and air. Not a bit of perlite goes to waste since all sizes have specific uses.

The Path of Perlite

Volcano

Perlite forms when lava is submerged in water and cools so quickly the water is trapped in the glass. Raw perlite ore is very dense, but softens at extreme temperatures.

Mining

This is not your typical mining process. It’s all done above ground using an open-pit method of ripping with a bulldozer and, when needed, blasting. It’s safer, more environmentally friendly and sustainable, with less than 1% of perlite mined to date.

Transportation

Perlite is transported by train as dense ore to reduce costs and environmental impact. One train can transport as much as 300 trucks and produces 8 times less CO2 and 3 times less nitrogen emissions.

Processing

Raw perlite ore is crushed, dried, screened and then heated at temperatures ranging from 1600° F to 1800° F. When it pops like popcorn, it expands up to 20 times its original size. And since only the physical form is altered, there are no by-products.

Final Form

Once expanded, perlite turns from gray to white, is lightweight, and has insulated glass bubbles that can hold water and air. Not a bit of perlite goes to waste since all sizes have specific uses.